We’re going to perform an experiment to see if PLA filament will break from sitting in PTFE tubing. And will moisture cause it to snap even in a dry environment? Plus explain what “mechanical stress” means in this context.

Back when I recorded the “Why Does My Filament Keep Breaking?” (https://youtu.be/SvpSxHLotMI) video I made the statement that mechanical stress was causing the filament to break over time. The filament in question sits in a dry box in a humidity controlled room.

Both on the printer and in the box I noticed that the filament would snap when held straight. Which is an unnatural condition for the thermally formed PLA and what “mechanically stressed” refers to (in this case).

There were numerous responses questioning PTFE tubing playing a roll in the filament breaking as well as some form of moisture ingress into the filament.

Moisture can cause problems with PLA, to be sure. But not this particular problem in a dry environment.

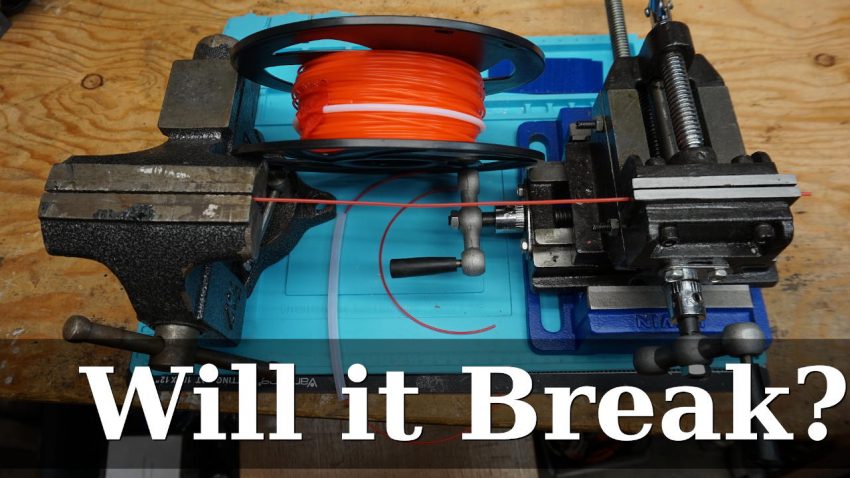

I don’t believe either of those to play a significant roll in this case so we’re going to perform a quick experiment to A) explain what mechanical stress is (for this case) and B) show it breaking filament that is perfectly fine after the same amount of time on the roll sitting next to it on the bench. Inside and outside of PTFE.

If you’d like to play along at home you can use a couple of books to hold the filament perfectly straight (not looped) between them.

Let’s see what happens after a couple of days of artificially mechanically stressing PLA filament to see if it will break!