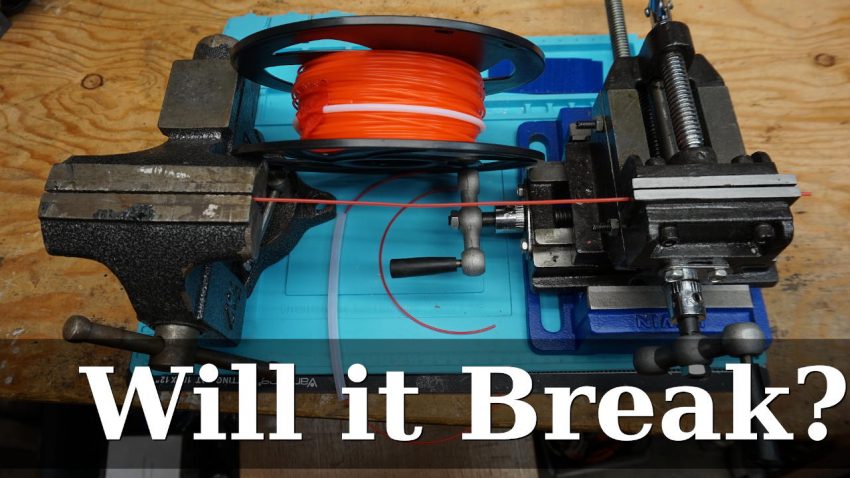

We’re going to perform an experiment to see if PLA filament will break from sitting in PTFE tubing. And will moisture cause it to snap even in a dry environment? Plus explain what “mechanical stress” means in this context. Back when I recorded the “Why Does My Filament Keep Breaking?” (https://youtu.be/SvpSxHLotMI) video I made the…

Category: 3D Printing

Anything related to extrusion printing. Generally with plastics such as ABS, PLA, PET, and Vinyl.

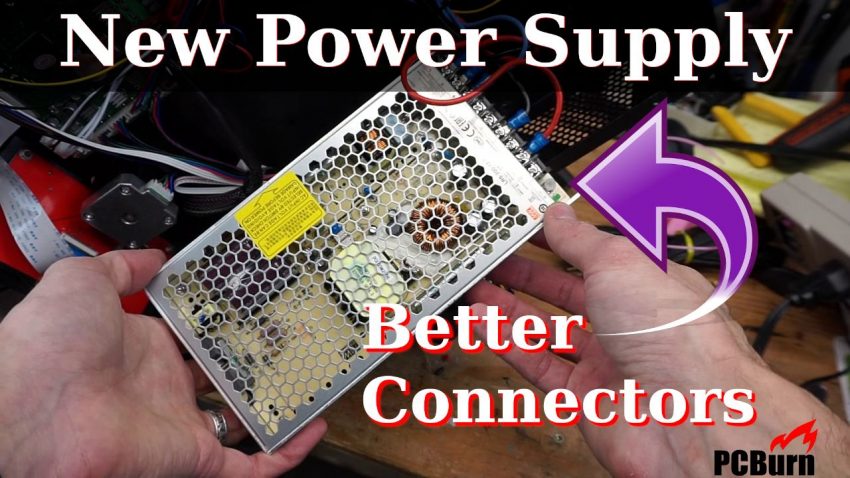

3D Printer Repair – Replacing and Rewiring a Power Supply

Clean power for your 3D printer is a must-have item if you don’t want mystery problems cropping up. In todays segment on 3D printer repair I’m re-wiring this one of my printers and replacing the sketchy no-name power supply with a (better) quality Mean Well unit. There’s no part of a 3D printer that touches…

SMD Spool Up for a Clean Workbench – DIY Solution

Spooling up loose SMD part tape for surface mount components makes sense. So you’re suffering under the weight of plastic bags filled with tiny parts on paper rolls? Read on for a slick SMD Spool solution for storing them. Suddenly realizing my workbench was too cluttered (in the Phrozen Sonic Mini review) I decided to…

Phrozen Sonic Mini Review – Should I Buy It?

While I don’t often write reviews of products these days I just purchased a Phrozen Sonic Mini. So I’d like to share setup details and my impressions of the printer with you. Update: I’ve added a list of 3D Resin settings for the Phrozen Sonic Mini. I purchased this UV printer directly from Amazon for…

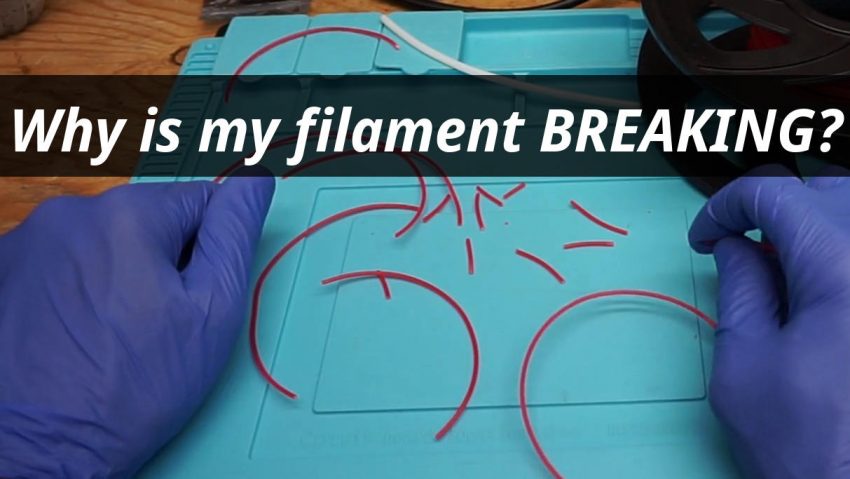

Why does my PLA filament keep breaking?

My PLA filament has started breaking into small pieces. But only under certain conditions. And I would like to know why. So overnight I’ve set out a few test pieces to see how they react. Here’s what I’m working with and the tests I’ve performed on it. You can see how it reacted in the…

Creating a 9 Pin Joystick Cable End – 3D Printing DIY

9 Pin joystick cable pigtails have been amazingly hard to find. And I need to re-cable old joysticks for the Genesis since the cheap replacements are mostly garbage. So I’ve finally resorted to making my own. To be clear DB9 connectors are easy to source. I’ve got a stack of them here for an unrelated…

DIY UV Resin Curing Station – Make Your Own UV Resin Curer

UV Resin for small batch prototyping in the home shop has come down in price dramatically. Now that it’s an affordable option for making components I’m working on the Wanhao D7 printer again. Along with the printer there are some other necessities. You need rubbing alcohol to clean the prints, plastic containers, and something to…

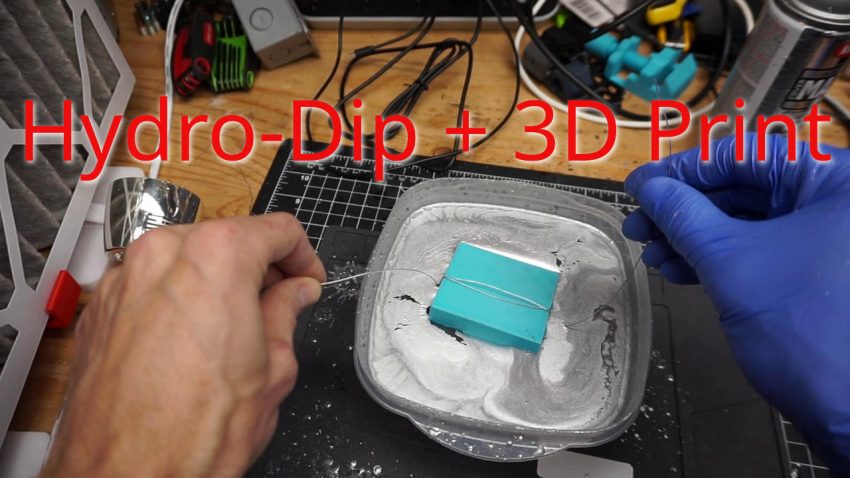

Hydro Dip Paint Surface Coat PLA 3D Prints

Hydro dip (or water transfer printing) is a process to paint objects by dipping them in a scum of acrylic paint floated on water. Since that seems pretty straight forward I’m going to try it for painting PLA prints! There’s two caveats here. First, I’m using chrome paint which may react a bit oddly to…

DIY Mic Stand with Printed Cable Retention Brackets

I’m building a weighted base DIY mic stand! Rather than buying it in off Amazon I decided to DIY it and build my own.

Digital Caliper via USB (Vernier) for DRO – Just 3$

A digital caliper was at one point the domain of the wealthy. The rest of us had to slug along with our slide calipers and suck it up. And then came the silicon revolution. Everything became smaller, cheaper, and easier to mass produce. Now you can pick up a set of digital calipers for as…