Are you sanding down 3D prints? Metal bar-stock or tubes? Wood? A DIY Sanding pad could make a great addition to your toolchest! When the surface you’re sanding is flat a hand sander or stick with sandpaper tacked in works just fine. But for situations where you’ll be working a rounded surface something more pliable…

Category: Shop Tools

Digital Caliper via USB (Vernier) for DRO – Just 3$

A digital caliper was at one point the domain of the wealthy. The rest of us had to slug along with our slide calipers and suck it up. And then came the silicon revolution. Everything became smaller, cheaper, and easier to mass produce. Now you can pick up a set of digital calipers for as…

WowStick 1F Plus: Taking a Look

WowStick’s 1F Plus is, on the face of it, a decent low-torque power screwdriver. From the spec sheet it appears to be limited to low, non-plastic destroying torque on drive and a bit higher torque on reverse.

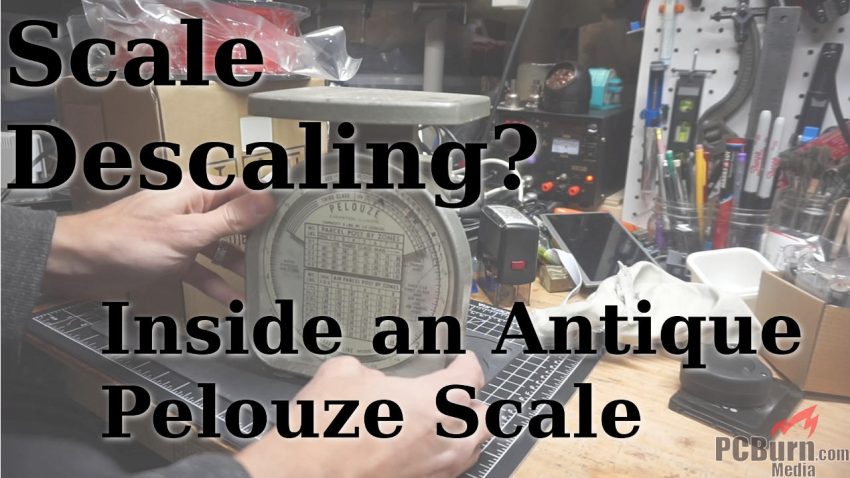

Pelouze Scale: Inside an Antique

The Pelouze scale I use for quick weights has stopped zeroing out. Something appears to be sticking. So I’m pulling it’s tabs for a look inside!

Old Hydronic Furnace to New DIY Metal Melter

Re-use is a common theme. And metal is one of the easiest things you can possibly re-use. But to re-use it you first need a metal melter to melt down the old metal before casting, forging, hammering, milling, or whatever process you’ll use to turn it into something new.

Box Fan Filter Variable Speed Fan Build

Building your own box fan filter is a great way to reduce the amount of dust in your workspace. I’m going a step further and adding in a variable speed motor control!