NES Clone systems have been around for some time now. But the Retro Entertainment System I’ve got on the bench today is of a newer vintage. 37 years after the NES first hit US shores how are these new clones systems being made? In the early 2000s VR Technology started releasing their VTxx line (datasheets)…

New Bright RC Car Teardown – Even cheaper than it looks

My first step to any electronics mod is to do a teardown and see what I’m working with. New Bright’s RC F150 truck looks like an ideal candidate from the outside. But is it going to make the cut for replacement electronics? And that’s what I was aiming to find out by digging into the…

Phrozen Sonic Mini Review – Should I Buy It?

While I don’t often write reviews of products these days I just purchased a Phrozen Sonic Mini. So I’d like to share setup details and my impressions of the printer with you. Update: I’ve added a list of 3D Resin settings for the Phrozen Sonic Mini. I purchased this UV printer directly from Amazon for…

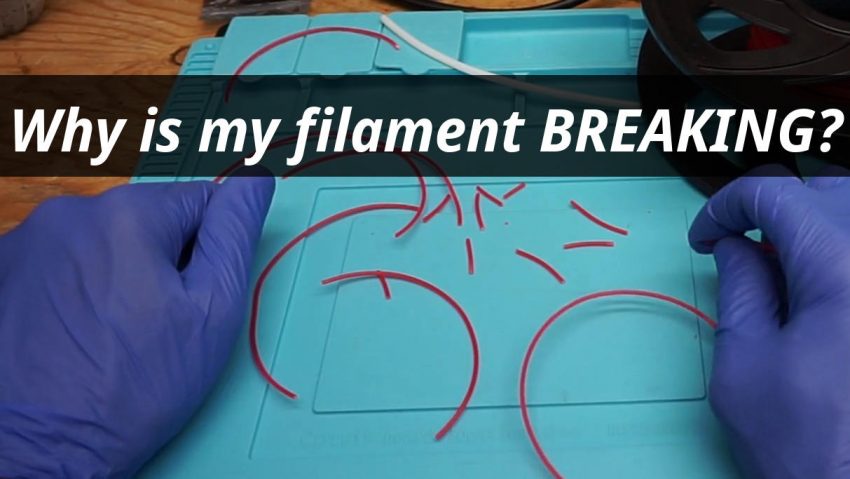

Why does my PLA filament keep breaking?

My PLA filament has started breaking into small pieces. But only under certain conditions. And I would like to know why. So overnight I’ve set out a few test pieces to see how they react. Here’s what I’m working with and the tests I’ve performed on it. You can see how it reacted in the…

Creating a 9 Pin Joystick Cable End – 3D Printing DIY

9 Pin joystick cable pigtails have been amazingly hard to find. And I need to re-cable old joysticks for the Genesis since the cheap replacements are mostly garbage. So I’ve finally resorted to making my own. To be clear DB9 connectors are easy to source. I’ve got a stack of them here for an unrelated…

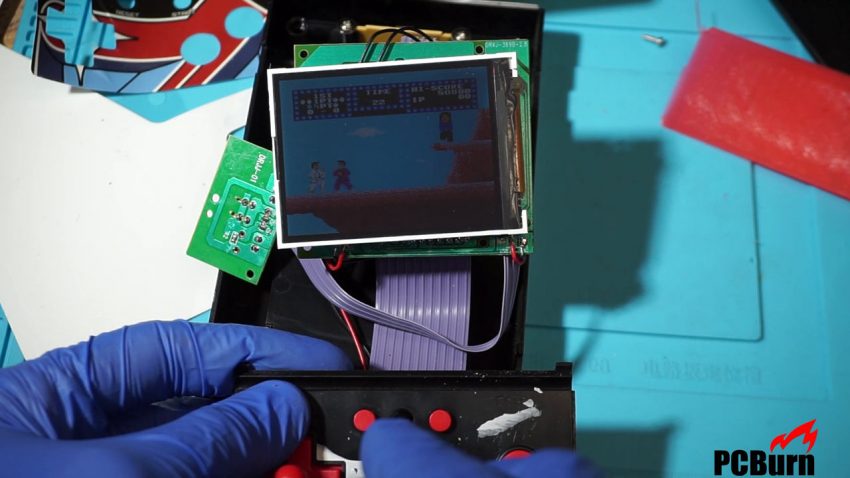

Data East Karate Champ “My Arcade” Teardown

Data East released Karate Champ, a twin stick fighter, nearly 40 years ago in 1984. Fast forward to 2017 and “My Arcade” releases one of their mini arcades based on it. And I’m tearing it apart. These mini arcade boxes are fairly similar to the Genesis clone I recently took apart. Although they lack a…

DIY UV Resin Curing Station – Make Your Own UV Resin Curer

UV Resin for small batch prototyping in the home shop has come down in price dramatically. Now that it’s an affordable option for making components I’m working on the Wanhao D7 printer again. Along with the printer there are some other necessities. You need rubbing alcohol to clean the prints, plastic containers, and something to…

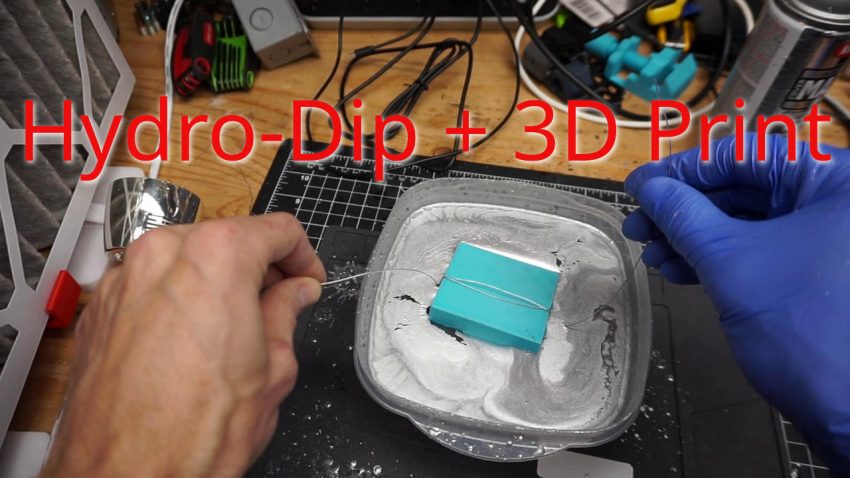

Hydro Dip Paint Surface Coat PLA 3D Prints

Hydro dip (or water transfer printing) is a process to paint objects by dipping them in a scum of acrylic paint floated on water. Since that seems pretty straight forward I’m going to try it for painting PLA prints! There’s two caveats here. First, I’m using chrome paint which may react a bit oddly to…

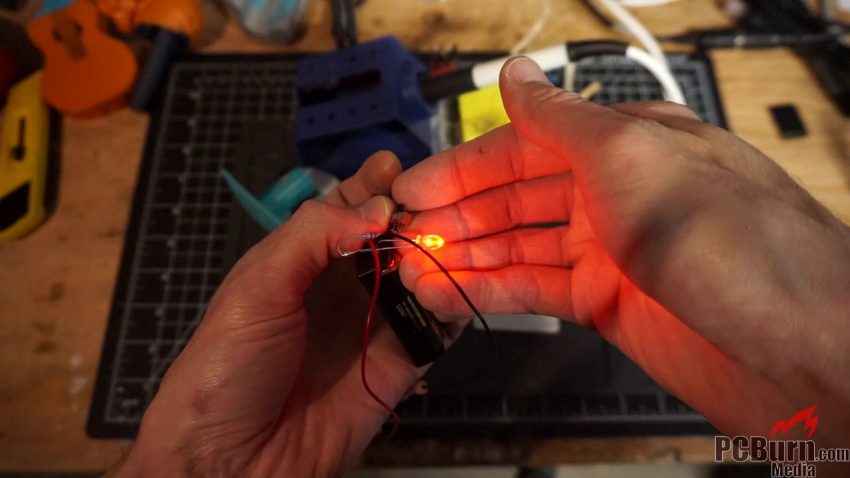

Quick Switched LED Light Circuit Using Just 4 Components!

LED light circuits are a fun component to add to any build. I’m adding one to the Sega Genesis clone I recently looked at! In this video I take a look at electronic components I commonly use to make cheap DIY LED lights.

Sega Genesis Clone: The 16 BIT Mega Drive 2

Sega Genesis entered onto the market at the very tail end of the 80’s. This was during the fourth generation of video game console alongside the Super Nintendo/Super Famicon and Neo-Geo. This particular unit, unfortunately for me, didn’t come out then and is a horrible pile of failure. Unfortunate because what I was actually trying…