I’m building a weighted base DIY mic stand! Rather than buying it in off Amazon I decided to DIY it and build my own.

Digital Caliper via USB (Vernier) for DRO – Just 3$

A digital caliper was at one point the domain of the wealthy. The rest of us had to slug along with our slide calipers and suck it up. And then came the silicon revolution. Everything became smaller, cheaper, and easier to mass produce. Now you can pick up a set of digital calipers for as…

PETG Filament – is the Cheapest on Amazon any good?

We’re once again taking a dive into the bargain bin at PCBurn, this time for PETG filament from Amazon. At 12.83, shipped, it’s certainly one of the cheapest filaments I could find. Normally I’m leery (despite what the cheapest PLA on EBay videos I’ve made might have you believe) about running cheap filaments through my…

Motorized Turntable for Video, Photo, and 3D Scanning (DIY)

Have you ever wanted to take a video, photos, or scan an object? Do you need a motorized turntable to move the object while this is done? Then have I got the design for you. Maybe. As it turns out an (ultra) cheap louver stepper isn’t the easiest type of motor to step (relatively) smoothly.

Tablet Teardown of the U30GT Android Tab

Have you ever wondered what’s inside a tablet computer? It might be a bit more general purpose than you think. And with parts more useful than the pong console. The Cube U30GT has reached the end of it’s life and I’m scrapping it for parts in this tablet teardown.

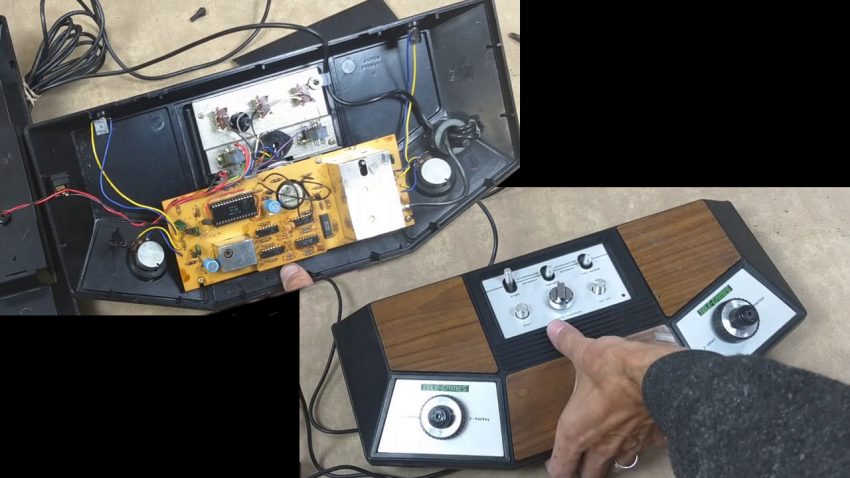

Sears Tele-Games (APF TV Fun 400) Teardown

During the late 1970’s arcade games were just coming into vogue. Capitalizing on the trend General Instruments released their “Pong on a chip”, the AY-3-8500 and it was picked up for the Sears Tele-Games console.

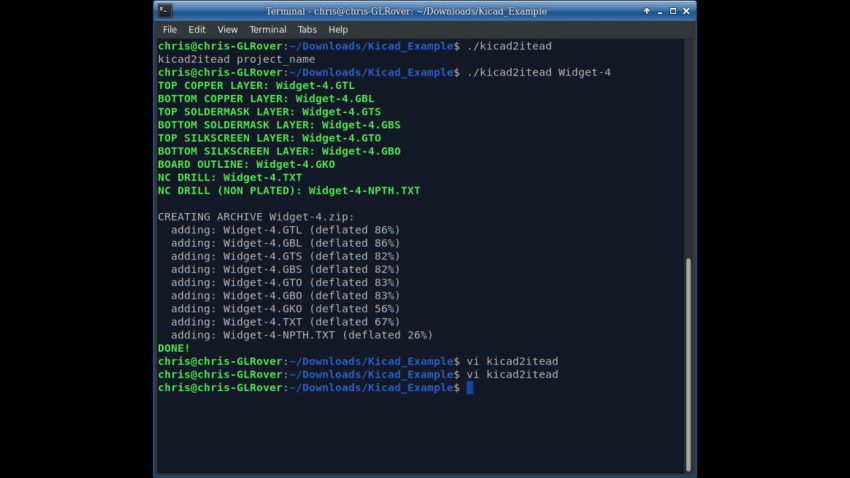

KiCad iTead Studio File Rename Program “kicad2itead”

KiCad has changed the filename format used when creating Gerber output files. Due to this the original “kicad2itead” Kicad iTead Studio rename script no longer works as expected.

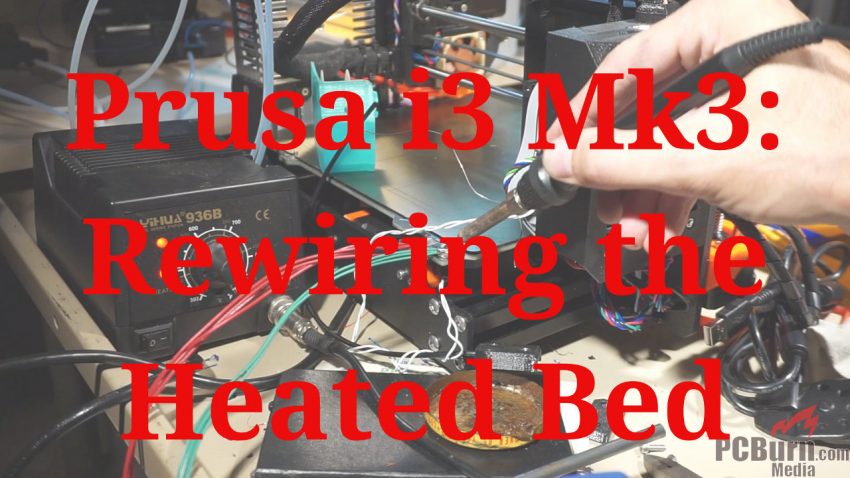

Prusa i3 Mk3: Rewiring the Failed Heatbed

The Prusa i3 Mk3 has had a heatbed failure. The problem’s diagnosed and we’re re-wiring the bed to get it heating properly again.

Heated Bed Cable Replacement on the Prusa i3 Mk3

Recently the heated bed failed on my Prusa i3 Mk3 (from Prusa 3D). But on the up-side it wasn’t the bed itself, but the cables. So I seized the opportunity to make a video of the troubleshooting process. There’ll also be a follow up video on what replaced the original cable.

WowStick 1F Plus: Taking a Look

WowStick’s 1F Plus is, on the face of it, a decent low-torque power screwdriver. From the spec sheet it appears to be limited to low, non-plastic destroying torque on drive and a bit higher torque on reverse.